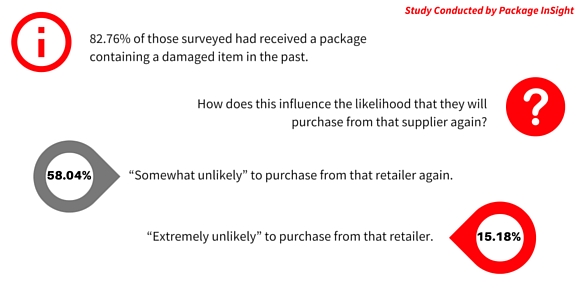

You’ve been eyeing that new kitchen gadget for a while and decide to purchase it online. You wait for the package to arrive. When it does, you notice the box is beaten up and the product is broken. Would you consider purchasing from the same retailer? According to a recent study from Package Insight, customers are likely to think twice. About 54% reported that they would be “somewhat unlikely” to purchase from the supplier again, while 15% said they would be “extremely unlikely.”

Why Is Protective Packaging Important?

As a product manufacturer or a packaging design company, the last thing you want to do is frustrate your customer. Making sure your product is secured with protective packaging will help create a more positive end-user experience.

Bonding foam (EPS, polyethylene and urethane) or cardboard inserts/fitments to corrugated packaging material is a common way to protect your product, forming a barrier between the product and outside forces. Such protection ensures that the product reaches its final destination undamaged and in perfect working order. This decreases the likelihood of product returns and replacements as well as filing shipping claims –all of which hurt your bottom line.

Study Conducted by Package InSight

Double-Sided Tape in Protective Packaging: Bonding Foam and Cardboard Inserts

Pressure-sensitive, double-sided tape is very effective for bonding foam substrates and cardboard inserts to packaging materials. Not every protective packaging application is the same, which is what makes a versatile product like double-sided tape a good solution for securing your product.

Double-sided tape, like Adhesive Squares, offers numerous benefits:

- Instant bond – As soon as you apply the adhesive and compress the substrates, you get an immediate bond. Unlike traditional liquid adhesives, you won’t have to wait for the adhesive to cure. You can quickly move on to the next step in your process.

- Custom sizes – Your protective packaging will vary depending on the product you wish to protect. For instance, some products will require bonding a wide surface area, while others may require a small area. Adhesive dots are versatile and can be customized to fit your exact specifications.

- Range of adhesive tack – Perhaps your protective packaging requires an aggressive, permanent bond to keep your product in place. Or maybe you want the protective packaging to be removable by the end user. A range of tack levels allows you to select the best fit for your application.

- No heat application – No heat eliminates burns, making it safer to apply adhesive versus foam bonding with hot melts where swirl/spray and roll coating is used to apply hot melts to foam.

As you explore protective packaging and adhesive options, please contact us if you have any questions or need guidance. Our line of Adhesive Squares double-sided tape accommodates many protective packaging applications. To chat with someone about adhesive options or request a product sample for your protective packaging, contact our technical service team at 1-800-844-1740 or use the contact form below.