If your process includes bonding substrates, then you’re no stranger to the wide range of adhesives available to get the job done. And as you know, not all adhesives are created equally.

In applications where bulk hot melt or a traditional tape is being used, a double-sided tape with pressure-sensitive adhesive squares can be used, too. With the availability of these three types of adhesives, each one has its advantages and disadvantages.

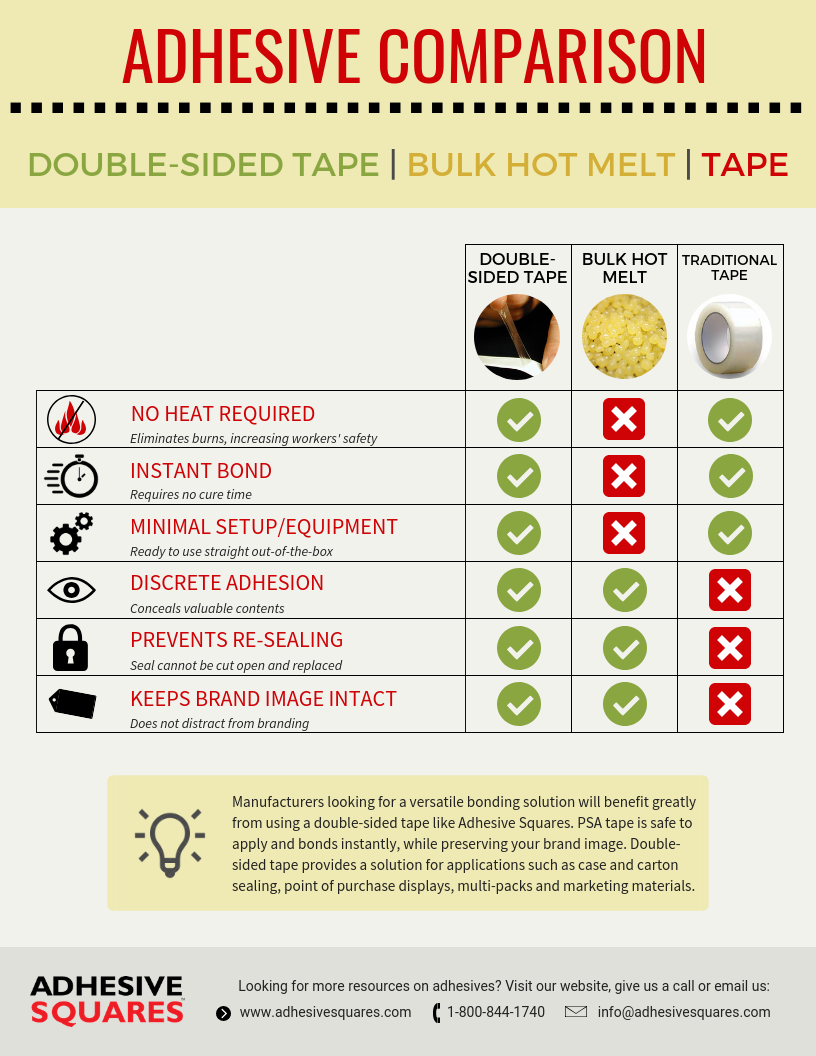

Some adhesives bond instantly, such as pressure-sensitive, double-sided tape and traditional tapes. Bulk hot melts, on the other hand, take time to cure. As a manufacturer, production speed is important when selecting an adhesive. Safety is an additional concern. Hot melts require heat, while double-sided tape and traditional tapes can be applied at room temperature, which eliminates burns. Safety and production speeds are just a few of the top priorities in manufacturing plants across the nation.

The comparison graphic identifies the key differences among double-sided tape, bulk hot melts and traditional tapes.

Compared to hot melts and traditional tape, double-sided tape on a liner with pressure-sensitive adhesives offers a great amount of versatility and capabilities for a wide range of applications. Whether you’re assembling a product or packaging a product, this type of tape is certainly a solution worth considering.

The graphic above is simply a guide to highlight the strengths and weaknesses of each adhesive. Some key factors you may review include production volume, safety concerns and customization needs. We always recommend working with a trusted adhesive supplier to identify the best solution for your application.

Our line of Adhesive Squares double-sided tape provides a valuable alternative to bulk hot melts and traditional tapes. For more information about Adhesive Squares or to request a product sample, contact our technical service team at 1-800-844-1740 or use the contact form below. We’re available 24/7 to discuss your specific application.